Enterprise Network Infrastructure

Built to Scale.

Your network is only as reliable as its cabling. We design and install TIA/EIA compliant structured cabling systems that support 10Gbps today and 40Gbps tomorrow—with warranties that outlast your building's lease.

For IT Managers & General Contractors Who Demand More

Whether you're an IT Manager inheriting a server room nightmare, or a General Contractor delivering tenant improvements on a tight schedule, you need a cabling partner who understands both the technical requirements and the business constraints.

Cat6 & Cat6a Copper

TIA-568-certified horizontal cabling supporting 1Gbps (Cat6) to 10Gbps (Cat6a) over 100 meters. Future-proof for PoE++, VoIP, and IP security systems.

Single-Mode & Multi-Mode Fiber

OM3/OM4/OS2 fiber backbone installations for MDF-to-IDF runs, building-to-building connections, and data center interconnects up to 10km.

MDF/IDF Room Build-Outs

Complete telecommunications room construction: racks, ladder rack, grounding, cable tray, environmental monitoring, and UPS integration.

Wireless Infrastructure

Survey-based WAP placement with dedicated Cat6a home runs per access point. Support for WiFi 6E/7 density requirements and PoE budget planning.

Conduit & Pathway Systems

EMT conduit, cable tray, J-hooks, and innerduct systems for industrial environments, parking structures, and exterior runs requiring physical protection.

Testing & Documentation

Every cable is Fluke DTX/DSX tested to TIA standards. You receive digital certification reports, as-built documentation, and cable schedules.

Not Just Installed—Certified, Documented, Warrantied

Any electrician can pull cable. We deliver a system: tested, labeled, documented, and backed by manufacturers who will stand behind the infrastructure for decades.

Fluke DSX Certification

Every single cable—not a sample, not a spot-check, every single one—is tested with Fluke DSX-5000/8000 equipment to verify performance meets TIA-568.2-D standards. You receive a PDF and CSV report proving PASS results for insertion loss, NEXT, PSNEXT, ACR-F, and alien crosstalk. This isn't optional documentation—it's the foundation for manufacturer warranty registration.

Zero Defects, Zero Callbacks

Poor termination causes 90% of network issues: intermittent connections, packet loss, and devices that drop offline randomly. Our technicians use Ideal/Klein punchdown tools calibrated to manufacturer specs, verify physical pair mapping with cable analyzers, and re-terminate any run that doesn't achieve perfect contact resistance. Your IT team won't spend hours chasing phantom cable faults.

25-Year Application Assurance Warranty

When installed by a certified partner using approved components (cable, jacks, patch panels, patch cords), manufacturers like CommScope, Panduit, and Belden provide 25-year system warranties covering both materials AND application performance. If a certified Cat6a run can't support 10G-BASE-T in year 15, they'll fix it at no cost. This isn't "we'll give you new cable"—it's genuine application assurance.

A Methodology GCs and IT Managers Can Trust

Scope & Survey

We review drawings, conduct site walks, identify pathway constraints, and document existing infrastructure. Deliverable: Detailed proposal with cable schedule, pathway design, and bill of materials for approval.

Rough-In & Pathway

Install cable tray, J-hooks, conduit, and firestop assemblies before drywall close. Pull cables with proper tension and bend radius. Coordinate with electrical/mechanical trades on pathway allocation.

Termination & Labeling

Punch down patch panels and jacks using manufacturer-approved tooling. Apply permanent machine-printed labels to both ends per client naming convention. Install keystones and faceplates with dust covers.

Test, Document, Handoff

Fluke-certify every cable. Generate digital reports. Dress cables in racks with velcro and cable managers. Walk client through as-built documentation and provide all test data on USB/cloud share.

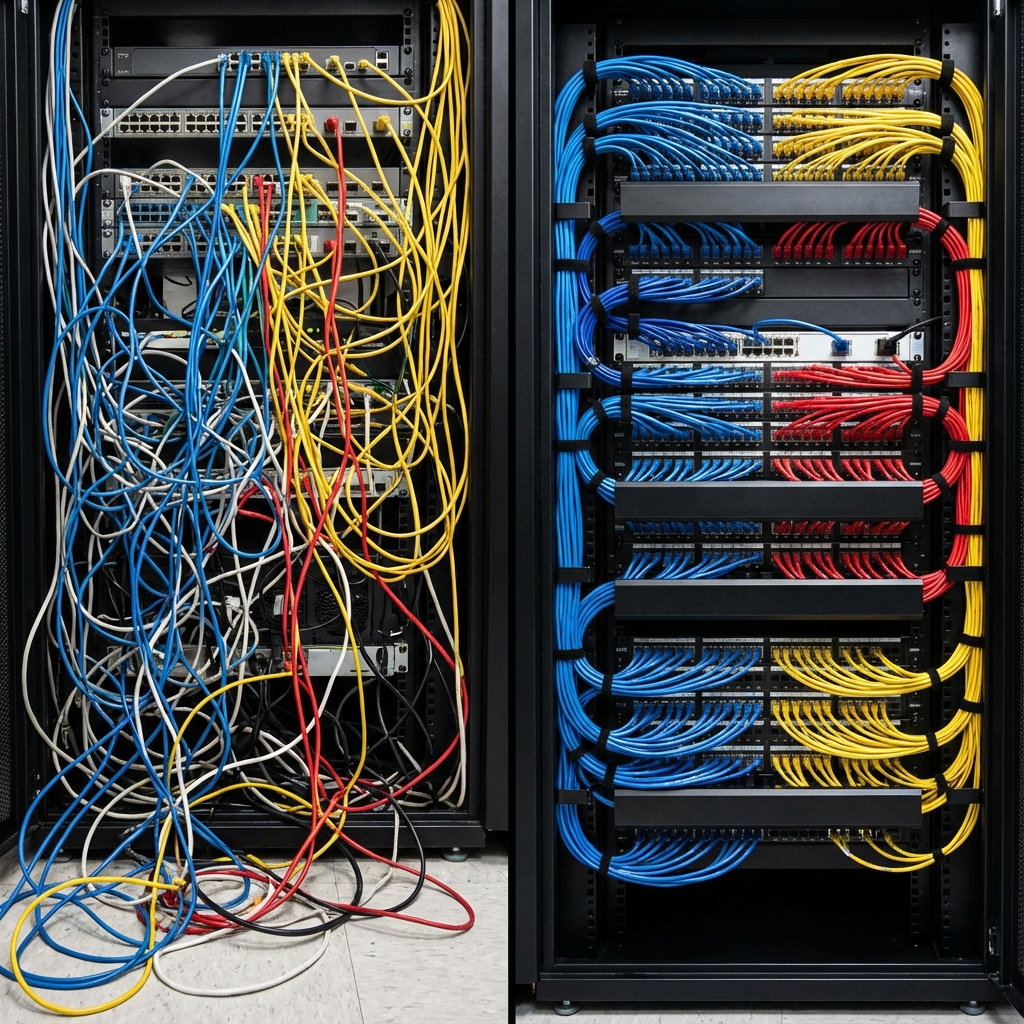

Why Enterprise Cabling Projects Fail

68% of network performance issues trace back to Layer 1—physical cabling. Yet construction budgets often treat cabling as an afterthought, handed to the lowest-bidding electrician. The result? Years of trouble tickets, failed PoE devices, and "intermittent" problems that no software patch will fix.

Problem: General Contractors often substitute Cat5e for specified Cat6a, or use non-plenum cable in above-ceiling runs to save $0.30/foot. These substitutions may pass a basic continuity test but fail spectacularly under real network load—especially when supporting PoE devices that draw sustained current through marginal connections.

Solution: Specification Compliance Verification: We document every material installed with photos and datasheets. All cable, jacks, and panels match the approved submittals. Change orders are issued before substitutions, never discovered after punch-through.

Problem: Cheap contractors test cables with $50 tone-and-probe kits that verify wire continuity but can't detect performance-killing issues like excessive untwist at terminations, kinked cables behind walls, or alien crosstalk from parallel runs. The cable "beeps" but can't sustain gigabit speeds or negotiate PoE.

Solution: Full Channel Certification: We test to TIA-568.2-D Level 2G standards using Fluke DSX-CableAnalyzer equipment—not just continuity, but insertion loss, crosstalk (NEXT, FEXT), propagation delay, and impedance. You receive digital certificates for every run.

Problem: The previous cabling contractor left no records. You don't know which patch panel port connects to which office. Adding a single drop requires hours of cable tracing. This isn't an edge case—it's the norm in 70% of the server rooms we inherit.

Solution: Complete As-Built Documentation: Every installation includes: labeled patch panels with office location, cable schedule spreadsheet (Excel/CSV), rack elevation drawings, and a PDF Fluke certification report. Future IT staff can add, move, or troubleshoot without calling us.

Problem: Installers stuff 50 cables through a 2" conduit rated for 30. Cables are kinked, bend radius is violated, and future expansion is impossible without ripping out walls. Fire-stop penetrations are also compromised, creating code violations.

Solution: TIA-569 Pathway Design: We calculate fill ratios per TIA-569 standards, specify cable tray/J-hook sizing for 50% spare capacity, and maintain documented fire-stopping at every rated penetration. Your building can scale without reconstruction.

FAQ

Your Network Deserves Better Than 'Good Enough'

Whether you're building out a new office or inheriting a legacy nightmare, let's design infrastructure that works today and scales for tomorrow. Request a scope review.

Accreditations & Memberships

Proud to be recognized by leading industry organizations